How important the hydraulic oil !

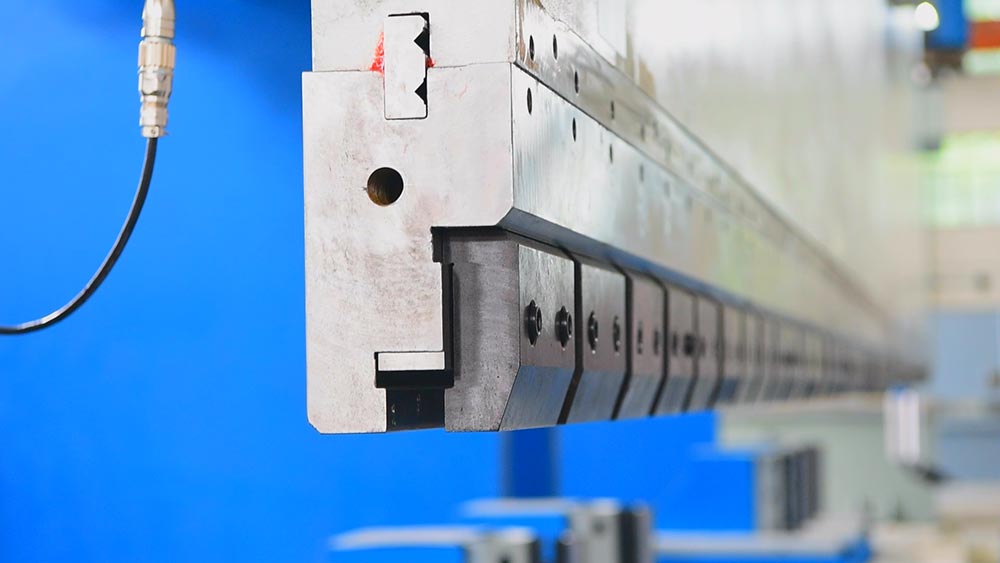

Hydraulic bending machines adopt hydraulic system. Hydraulic oil is an essential part of hydraulic control system. It plays an important role in energy transfer, abrasion resistance, system lubrication, corrosion prevention, rust prevention and cooling in the hydraulic system. Oil temperature is an important issue in the use of bending machine. When the weather is hot or the workshop temperature is high, the hydraulic oil temperature of hydraulic press brake can be easily raised after working for a long time.

WUXI SHEARCHY is a professional hydraulic machinery supplier in China. This passage will briefly introduce to you the harm of high oil temperature to bending machines and the cause of high oil temperature.

For the machinery industry, hydraulic oil temperature control between 30 degrees and 55 degrees is the best. At this point, the hydraulic oil viscosity, lubrication and wear resistance are in the best state, so the hydraulic system working efficiency is the highest.

The damage caused by too high oil temperature:

- The viscosity of hydraulic oil, volumetric efficiency and working efficiency of hydraulic system are all decreased. It will cause hydraulic oil leakage increase, and even make sheet metal bending equipment cannot work properly.

- The parts of hydraulic system expand due to overheating, which will damage the original normal motion gap between the parts. As a result, the friction resistance increases, hydraulic valve is easy to jam dead. At the same time, this will make the lubricating oil film thin, mechanical wear increases. Finally, the close fitting surface of the pump, valve, motor, etc. becomes invalid or useless due to wear.

- Accelerate the aging and deterioration of seals, shorter service life, and even lose its sealing performance, resulting in serious oil leakage of hydraulic system

- Oil vaporization, water evaporation, easy to cause hydraulic components corrosion. The oil oxidizes to form colloidal sediment, which can easily block the filter and hydraulic valve, making the hydraulic system unable to work properly

To sum up, too high temperature of hydraulic oil will seriously affect the normal operation of the hydraulic bending machine, reduce the using life of hydraulic components and increase maintenance costs. WUXI SHEARCHY hydraulic bending machine adopts advanced integrated hydraulic control system which limits the quantity of pipe connections, thus being more reliable and easy for maintenance. What’s more, for customers who need to use press brake in high temperature environment, we can customize hydraulic press brake with air cooling device.

If you are in need of hydraulic bending machines, welcome to visit our website for more details. Wuxi Shearchy will continue to share useful information about machinery with you. Stay tuned and we’ll give you more information when we can!