Press Brake Bending Accuracy

In sheet metal processing, all enterprises are committed to making their products close to zero error. However, in the actual process of machining, bending precision is more or less affected by various internal and external factors. In the processing, the work piece processing and forming are completed by numerical control bending machine. Therefore, the work piece machining accuracy depends on the precision of press brake to a great extent.

What affect bending precision in numerical control hydraulic press brake?

Factors affecting machining accuracy: spindle rotation error, guide rail error and bending die error. And if the bending machine wears, it will further reduce the bending accuracy.

Spindle Rotation Error

People who are engaged in machining know that the machine tool spindle is the benchmark for clamping work piece or mold. The spindle transmits motion and power to the work piece or mold. Therefore, the spindle rotation error will directly affect the accuracy of the processed work piece. The machining error caused by spindle rotation error is different with different machining methods.

Solutions:

- Properly improve the manufacturing accuracy of spindle and other machine parts.

- Select high precision bearings.

- Balance the high-speed spindle components

Guide Rail Error

The guide rail is the datum to determine the relative position of each component and also the datum of the machine tool movement. Bending machine guide precision requirements mainly have the following three aspects: the straightness in the horizontal plane, the straightness in the vertical plane, the parallelism of the front and rear guide. In addition to the manufacturing error of the guide rail itself, the uneven wear and installation quality is also an important factor causing the error of the guide rail. There are also transmission chain errors. It refers to the relative motion error between the transmission elements at both ends of the transmission chain.

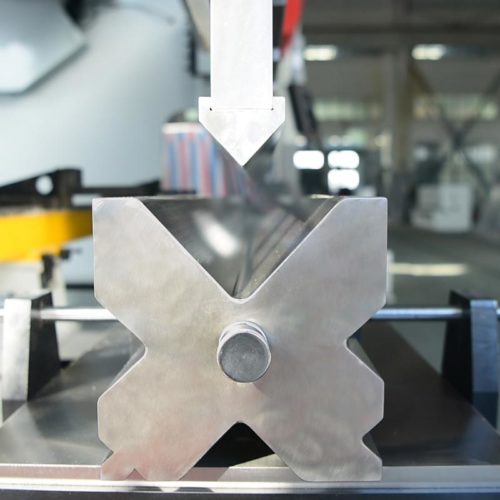

Bending Die Error

The effect of bending mold error on machining accuracy varies with tool types. The manufacturing error of the customized bending die will directly affect the machining precision of the work piece. The manufacturing error of common mold has little effect on the machining precision of work piece. Any mold in the bending process, it is inevitable to wear, and thus cause the work piece size and shape to change. The correct choice of material, geometric parameters and bending parameters can effectively reduce the wear of the bending die and improve the bending precision.

In addition, the correct use of the bending machine and mold is also conducive to the improvement of bending accuracy. When using a bender, the user must follow the rules. If you have any questions about Shearchy metal forming machines, please feel free to contact us!