Every product will have issues at one point in its usable lifespan and press brake machines are no different. Some press brake bending problems are more common than others. In this breakdown, we will look at the most common issues that users come across.

Problem 1: Why doesn’t the press brake bending machine move?

The problem:

The oil pump isn’t outputting oil and the Ram will not move.

Cause of the problem:

This issue happens when the pump is in the incorrect rotary direction.

How to fix this issue:

Interchanging the phase of the power supply is a known solution.

Problem 2: How to solve the abnormal oil pump?

The problem:

There could be a few problems here. The pump occurs an abnormal size and the pressure meter is unstable, the oil output pressure has decreased, or there is no output pressure at all.

Cause of the problem:

Four common issues cause this problem:

- The suction filter is blocked.

- More oil is needed in the oil tank.

- Oil is not getting in the pump and pipes.

- The components in the pump are damaged.

How to fix this issue:

This issue can be resolved in many ways.

- Clean the filter.

- Add oil to the level required.

- Replace the seal of the suction at the pipe joint and the end of the pump.

- Replace the component in the pump or replace the pump.

Problem 3: How to deal with oil leakage of press brake hydraulic system?

The problem:

There is leakage from the hydraulic valves, pipe joints, and/or cylinder.

Cause of the problem:

This issue is commonly one of two reasons:

- The connecting screw and pipe connector is loose.

- The seal is bad.

How to fix this issue:

The most common fixes to this issue are:

- Tighten the screw and connecter.

- Replace the seal.

Problem 4: Why is there no bending pressure in the hydraulic system?

The problem:

There isn’t pressure in the hydraulic system.

Cause of the problem:

This problem usually occurs for two reasons:

- The orifice and the core of the valve are blocked.

- The piston seal on the cylinder leaks.

How to fix this issue:

This problem is generally an easy fix in one of these two ways:

- Clean the orifice and the core valve.

- Replace the piston seal.

Problem 5: Why does the ram step down during pressing down?

The problem:

The Ram steps down during pressing down.

Cause of the problem:

This problem can occur for two common reasons:

- The balance pressure in the valve isn’t great enough.

- The guide rail is too tight.

How to fix this issue:

This problem can usually be solved in two simple ways:

- Increase the balance pressure.

- Loosen the guide rail.

Problem 6: Why does the ram drop down by itself?

The problem:

The ram is dropping on its own.

Cause of the problem:

This problem is caused by one of two different issues:

- The valve has become stuck.

- The piston seal of the cylinder is leaking.

How to fix this issue:

This issue can be fixed with simple cleaning and in some cases a replacement.

- Clean or replace the 1.0300 valve.

- Replace the piston seal.

Problem 7: Why there is pressure in the system as soon as the press brake start running?

The problem:

The press brake contains pressure in the system at the start of the operation.

Cause of the problem:

If you’re experiencing the press brake bending problems, there are two common causes:

- The orifice is stuck.

- There is an electrical fault.

How to fix this issue:

Most commonly this issue has a simple fix.

- Clean the orifice.

- Check the wiring for faults, exposed wires, or out of place wires.

Problem 8: How to solve the high noise in the high-pressure filter?

The problem:

The high-pressure filter gives off high noise.

Cause of the problem:

This is most commonly caused by a blockage in the high-pressure filter.

How to fix this issue:

Unfortunately, this press brake bending problems do not have an easy solution. You will need to replace the core of the high-pressure filter.

Problem 9: Why doesn’t the ram work properly?

The problem:

The ram is not retracting automatically, cannot retract after the upper die press or bottom die press, or the ram cannot move down at certain positions.

Cause of the problem:

The selected tools in the computer are not the actual tools in use.

How to fix this issue:

This press brake bending problem can be solved by verifying that the selected tools and tools in use are the same.

Summary:

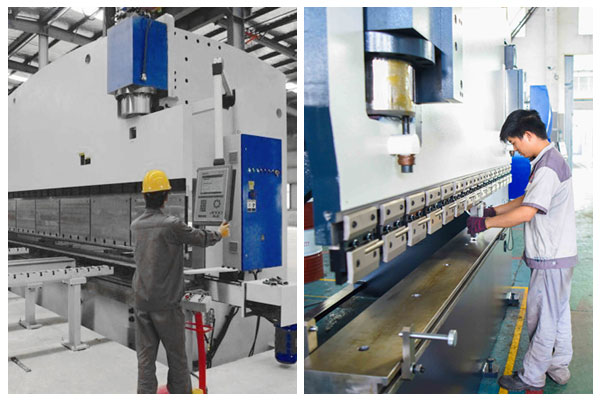

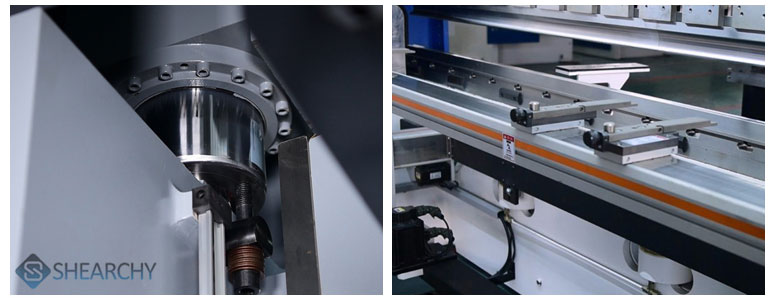

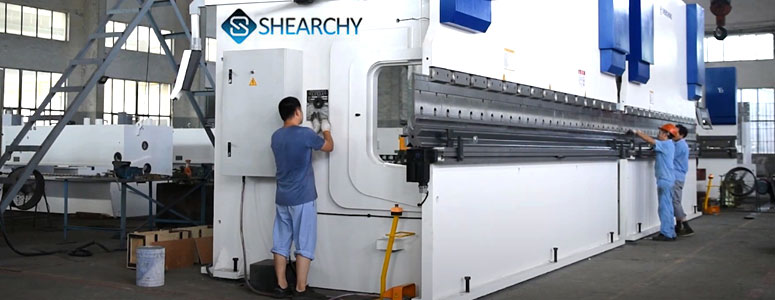

A press brake bending machine is high quality and expensive machine. These machines require proper care to keep them in working conditions, but a poorly manufactured machine will require more attention than a properly manufactured one. Before purchasing a press brake bending machine, make sure to do your research on which companies produce the highest quality to reduce the issues you might face.