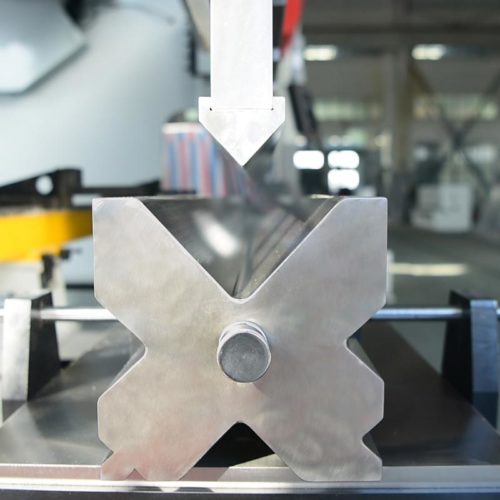

What is the minimum bending size of Brake Press Dies? Generally, when bending freely, the bending radius is 0.156 times of the opening distance of the lower die. At the same time, the opening distance of the bending mould shall be 8 times of the thickness of the metal material.

Hydraulic Press Brakes Minimum Bending Size

Sheet Metal Bending Problems and Useful Tips

Example 1:

When using a 0.5 inch (0.0127meter) opening to bend mild steel 16, the bending radius is approximately 0.078 inch. If the bending radius is less than the thickness of the plate, we must use the die with the bottom bracket. However, the bending pressure of lower dies with the bottom bracket is about 4 times larger than that of the free bending.

Example 2:

In generally, professional cnc press brake supplier Shearchy think that the spring back angle of the free bending die on the new hydraulic brake press is ≤ 2 °, and the bending radius is equal to 0.156 times of the opening distance of brake press dies. For the bending of the bottom supporting die, the die angle is generally 86 ° ~ 90 °. In addition, at the bottom of the stroke, there should be a gap between the punch and die slightly larger than the material thickness. The forming angle will be improved. Because the tonnage of the bottom holding die is large (about 4 times of the free bending). So it reduces the spring back stress within the bending radius.

Example 3:

In the case of not using the arc mold, if you want to fold out the work piece with radian, you need to select the mold with small cutting edge. The relevant mould needs processing according to the size of semicircle. At advance, process according to drawing and relevant mark line on mould. And then you can use it to make a circle bending.

Example 4:

If plate bending machine used to fold large arc, it is necessary to customize an arc device equipped with upper and lower dies. Due to the strong pertinence of this kind of mould, it belongs to customized press brake punches and dies. It can only be suitable for arc bends of a certain radius. Therefore, it is not a universal die and can not meet all large-scale arc bending.

We all know that mold design is very important. At the same time, it has very high requirements for drawings. It requires designers to select or redesign according to the existing mold and work pieces drawings.

What material and size do you request for brake press dies?

Please kindly provide request details. WUXI SHEARCHY will manufacture best press brake die for you!