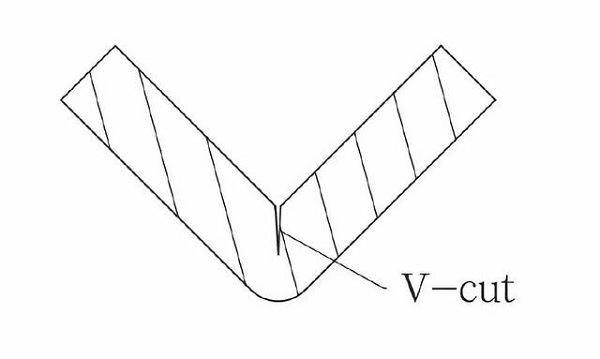

V Groove bending process: firstly, use V Groove Machine to scribe the V-groove at the position where metal sheet needs bending, and then bend on the ordinary press brake machine according to the demand.

V Grooving and metal bending features

It mainly includes the following three aspects.

- Work piece edge arc radius is small without creases.

- Reduce the tonnage required for sheet metal bending equipment.

- Strengthen the control of bending complex shapes work pieces or material resilient.

More detailed information about sheet metal grooving bending process, you can visit related articles:

Numerical Control V Groove Machine Bending Process

Slotting mode of V-groove

In sheet metal production, horizontal or vertical cnc grooving machines are often used to V-groove metal sheets. Users place the metal plate on the v grrove machine for positioning, and then input the thickness and other data. CNC groove machines will automatically adjust the blade and groove metals.

Slot Angle Setting

From the point of bending process, it can be seen that the metal sheet has different degree of spring back deformation in the bending process, which results in the deviation of bending angle.

V-shaped grooves in the open, you can rationalize grooving according to the bending angle of work piece. In general, the groove angle of V-groove is 1-2 degrees larger than that of bending forming. So, this would be good to avoid bending angle error caused by the rebound.

Selection and number setting of grooving cutter

Types and selection of tools

The main types of v groove machine tools are diamond top angle groove cutter, square groove cutter, triangle cutter, circular cutter, etc. Choose the right tool according to the different shape and angle of V-groove. When planes the ordinary V-groove, the tools’ angle should be smaller than that of the V-groove.

Setting the number of tools

When doing deep grooving on the longer size plate, the path of continuous grooving with a single tool is longer, which is easy to cause tool overheating and wear. So, there will be problems such as worse grooving effect and bigger burr. Therefore, in addition to setting the feed rate, you also need to set the number of cutting tools working at the same time under such circumstances. In this case, we usually recommend customers to use 3 to 4 knives to work at the same time. This not only ensures the quality of grooving, but also improves the work efficiency.

V Groove Depth and Residual Thickness Settings

These are two important things in metal plate v groove machine working.

When the plate thickness is fixed, the grooving depth and residual thickness are the corresponding values. According to the requirement of bending process, please set a residual thickness value first. Generally, the default is 0.8mm, and the minimum is not less than 0.3mm. Then, according to the thickness, set the number of cutters and the depth of feeding. Because of burr control and tool protection, the feed volume should not be too large. Generally, the first groove depth should not exceed 0.8 mm. Moreover, you should use at least two knives, not one grooving step to finish all.

Wuxi Shearchy provides two kinds of CNC grooving machines: CNC Horizontal V Grooving Machine and CNC Vertical V Grooving Machine. Welcome to contact us with your demands!